Core Competencies/Processes

Jedco’s capabilities have provided customers with high-quality products, forming lasting relationships. With over 120,000 square feet, our facilities house the machinery and man-power, with two full shifts. We stand behind our work 100% and specialize in the following processes:

Machining

Laser Machining, Drilling and Welding

- Through commonly owned company (Laser Access)

Exotic Metal Forming

- Draw Forming

- Spin Forming

- Hydro Forming

- Deep-Draw Forming

- Ring-Expand Forming

- Press-Brake Forming

Sheet Metal Fabricated Assemblies

Hot Forming and Superplastic Forming

- AMS 4901; AMS 4919; AMS 4911; AMS 5596

Hot Forming

- Inconel

Welding (TIG/Resistance/Laser/Plasma)

Non-Destructive Testing

- FPI

- X-Ray

- Pressure Testing

Parts

Many of the parts we supply have evolved and require innovation and fresh thinking. Our engineers and designers rely on years of experience and training to ensure that the quality of each part is meeting and exceeding expectations.

Part Family Focus

- Titanium Fabrications

- Combustion Chamber Assemblies

- Transition Ducts

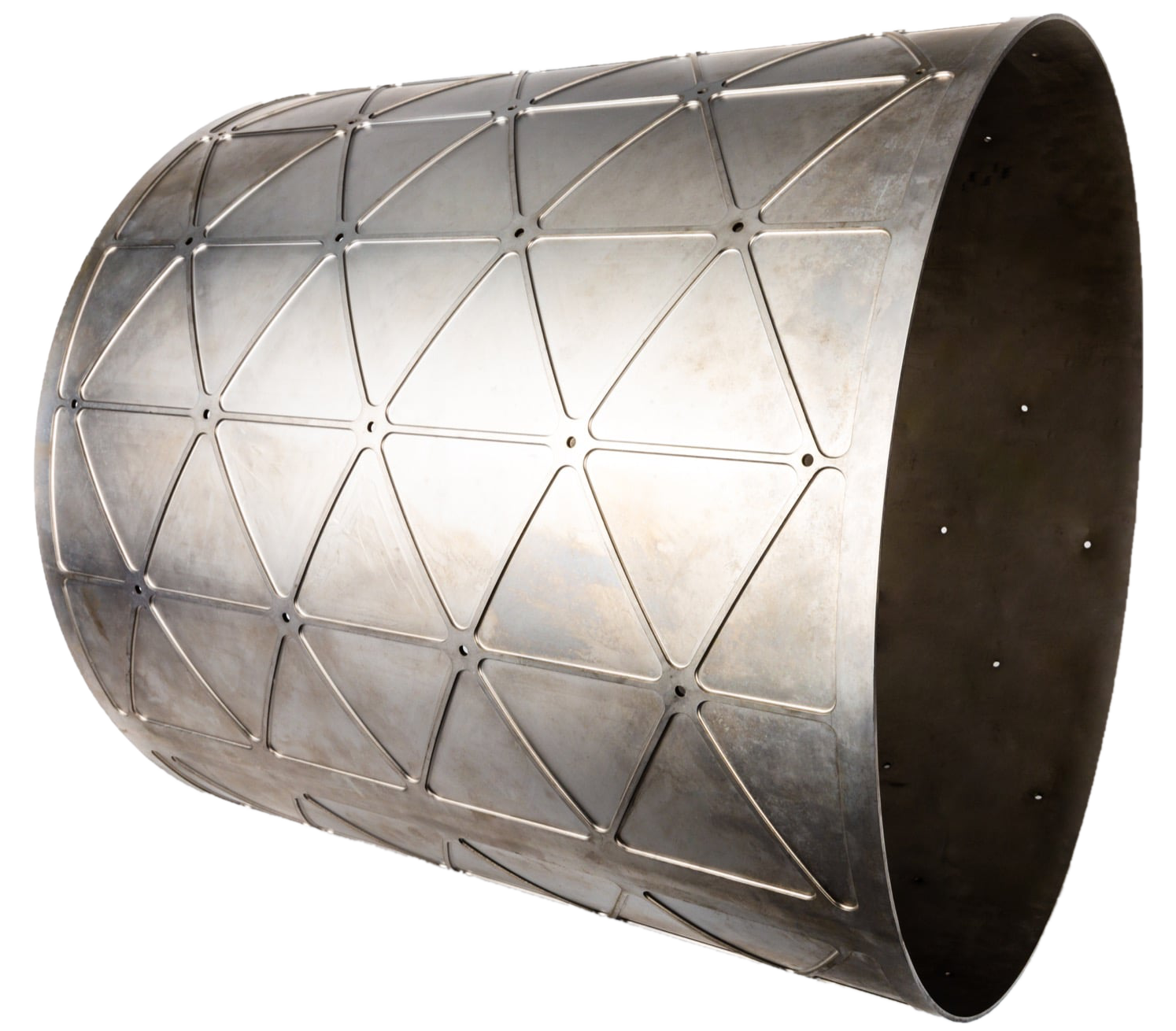

- Chem-Milled Augmenter Ducts

- Iso-Grid Formed Assemblies

- Heat Shields

- Exhaust Nozzles/Mixer Ducts

JedCAP

Jedco

Chem-Mill

Alternative

Program

Produces weight reduction pockets with reduced lead-times and costs, incorporated into current print specifications and an engineered profile definition, using an alternative to chemical-milling.